See how Videojets technology helps Philip Morris with their Pack Coding & Serialization

November 22, 2018 4:50 pmThis is how Videojets Lasers help Philip Morris with their day to day Pack Coding & Serialization. The process is fairly simple. Activate the Code Generator and quickly start production with the approved codes. Seamlessly integrate vision systems with our touch-screen panel. It is easy to setup and control the products for aggregation and compliance for Track and Trace purposes.

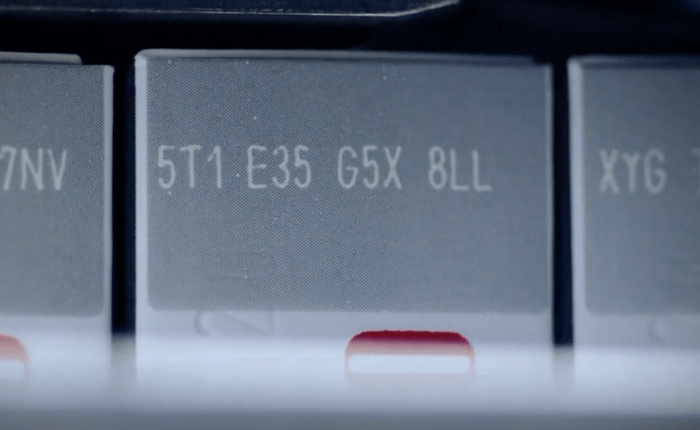

The laser marks directly to the pack, achieving a non-removable unique pack identification or serialization. 2D serialization provides enhanced security.

Videojet’s continous ink jet printers deliver the same precision to print CODENTIFY codes on packs or bundles. Reading bundle codes with a vision system automatically aggregates to the master case. Each bundle or carton has a unique ID to ensure aggregation of the packs that contains this bundle or carton, this provides the first level of aggregation for CODENTIFY. Labeling the clear overwrap provides an alternative to direct coding depending on the materials used. Master case aggregation in the next step to complete the produccion process before palletising, this achives the link between pack, bundle and maste case. Complete the CODENTIFY process with quality checks. Check master case number for details of associated bundles and cartons and the packs contained within each bundle and carton

Tags: 2d serialization, case coding, code generator, CODENTIFY, coding, ink jet, ink jet printers, laser, laser printers, serialization, Videojet