Description

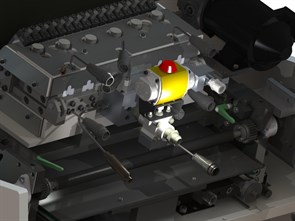

ExactCoatTM – the new line of precision slot dies – includes flex lip and rotary rod with flexible lip versions. ITW Dynatec will also offer positioners as well as a complete coating station. The new system will provide state-of-the-art solution with thinner and faster techniques as well as Adhesive Delivery System technology. ITW Dynatec’s Precision Hot Melt Slot Die system has guaranteed application performance resulting in faster production speeds and reduction of adhesive usage! This highly-accurate and reliable system prevents streaking, permits ultra-thin coatings and maintains industry leading coat weight accuracy. In addition, it provides real time monitoring of both pressure and temperature in the die! The new turnkey system includes the following components:

-

Melt system for the adhesive

-

Precision slot die

- Heated hoses and cabling

- Coating station including all dies adjusters

- Monitoring devices – both pressure and temperature

- State-of-the-art single PLC system capable to control: temperature of the entire system including the die, pump rates, as well as pressures